Table of Contents

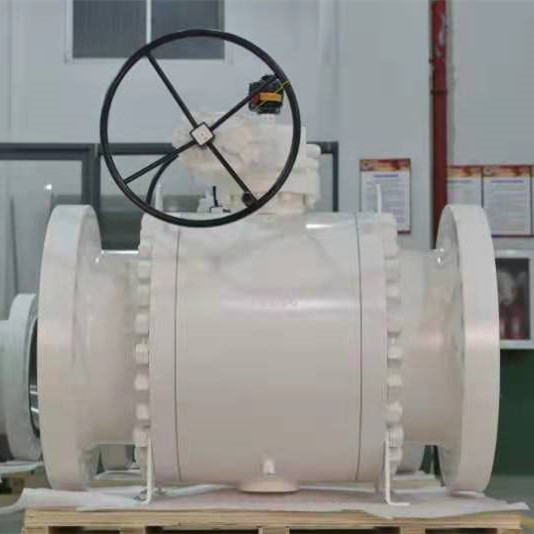

ToggleA trunnion valve is a type of valve that has two main parts: the trunnion ball and the valve’s casing. The casing attaches to the valve through threaded connections. To access the valve, the casing is opened, and the valve can be removed from the pipeline. The valve covering must then be installed on the valve.

Trunnion valves can be made of metal or thermoplastic materials. The thermoplastic material is good for high-temperature applications and offers a tight seal. However, these valves are more prone to failure if they are exposed to dirty or abrasive liquids. On the other hand, metal-seated valves are best for high-temperature applications and have higher corrosion resistance.

A trunnion ball valve has a similar structure to a ball valve, but it has an additional shaft that keeps the ball in place. This makes it easier to operate, and the two parts can be welded together. Another important benefit of a trunnion-mounted ball valve is that it requires less torque to operate.

Trunnion valves are often used in industrial settings. The trunnion keeps the ball inside the valve in place, which controls the flow of fluids. A trunnion ball valve has low operating torque, so it is a good option for applications where the differential pressure is relatively low.

How Do Trunnion Valves Work?

The basic working principle of a trunnion valve is a ball that is placed into a central shaft. The ball then rotates to an open or closed position. The valve contains a number of seals at the stem and seats that prevent fluid leakage. Additionally, there is an adjustable gland packing box to allow the valve to take on a variety of pressures. A typical trunnion ball valve has two bleeders for depressurization.

Trunnion ball valves are often used to control pressure and flow. The main sealing force comes from the differential in line pressure. When operating a trunnion ball valve, the piping system must be able to handle the sudden increase in pressure. Likewise, when opening a valve with little or no downstream pressure, the valve size must be properly selected.

There are two main types of trunnion valves. One type features fixed upper and lower stems. The other type features a floating ball. This type features a self-cleaning feature and automatic compensation. This type of valve is typically used to control the flow of fibers, solid particles, and highly viscous media.

Another type of valve offers a quarter turn. Moreover, it is soft seated and therefore not suitable for compressed air service. A soft seat may cause the valve to overtighten. In addition, it may be prone to corrosion and erosion. If you have high pressures or high temperatures, you should consider using a metal seated valve.

What Is The Structure Of the Trunnion Ball Valve?

A trunnion ball valve is a simple device that allows fluid to enter or exit a system. The valve has two parts: a stem and a ball. In addition, the trunnion ball valve has a metal spring and antistatic ball to prevent static charges. This valve also has a shoulder at the bottom that secures the valve.

The seal of a trunnion ball valve is composed of a square-shaped packing material. This material is mounted in the gap between the seat retainer and the ground. A spring is used to prevent the packing material from protruding into the valve’s gap.

A trunnion ball valve is similar to a traditional ball valve, except that it has additional mechanical anchors on the trunnion, making it more stable and easier to operate. In addition, it requires less torque than a conventional ball valve.

All About Trunnion Ball Valve?

Trunnion ball valves are made in different ways. There are top entry, side entry, and double block types. Each type is suitable for a different application. These valves can be purchased at different prices, depending on their price range and materials.

Side entry

The side entry trunnion ball valve is ideal for emergency shutdown applications. Its side entry design makes it easy to inspect the valve’s internal components while minimizing pressure drop. It is also fire-safe, thanks to its secondary metal seat. In addition, the valve features flexible graphite packing to prevent leakage at the body joints.

Top entry

A top entry trunnion ball valve is a simple design. Unlike side entry valves, top entry valves are easy to maintain and allow for faster access to the ball and valve trim. These valves typically have two entries, but some applications require three ports.

Double block

A Double block Trunnion ball valve combines the advantages of a single and double trunnion ball valve. This type of valve is widely used in a wide range of industries and applications, including high and low pressures. Moreover, it is known for its flexibility and adaptability.

Cost

A trunnion ball valve is a good choice if you’re in the market for a new valve. It is a highly durable valve that offers a number of benefits for the user. The trunnion design is also fire-safe and reduces the risk of environmental pollution. They are typically made of carbon steel, stainless steel, or Duplex. You can also find models with a non-corrosive coating on the internal wetted surfaces.

Maintenance

Proper maintenance is necessary for the performance of a Trunnion ball valve to run at peak efficiency. It is crucial to remove any debris that may be stuck in the valve’s seat, such as construction debris. In addition, it is important to periodically purge nitrogen from the line before turning the valve. The injection of sealant into the valve seat can reduce torque by up to 40%. Some operators keep synthetic lubricant in the valve seat to reduce friction. The lubricant also needs to be continually lubricated.

XINTAI Valve For Trunnion Valves

XINTAI Valve Co., LTD is a professional stainless steel valve manufacturer located in Wenzhou, China. The factory is spread over three thousand square meters and has acquired ISO9001-2000, API6D, and AZ authentications. The company is ISO certified and offers a wide range of high-quality valves for various industries.

The company’s philosophy is “Intelligent Manufacturing,” and it has a strong scientific research team. It also has a strong capacity for developing new products. Its diverse product range includes control valves, globe valves, ball valves, and sanitary valves. The company also produces valves with many different applications, including oxygen and power station valves.