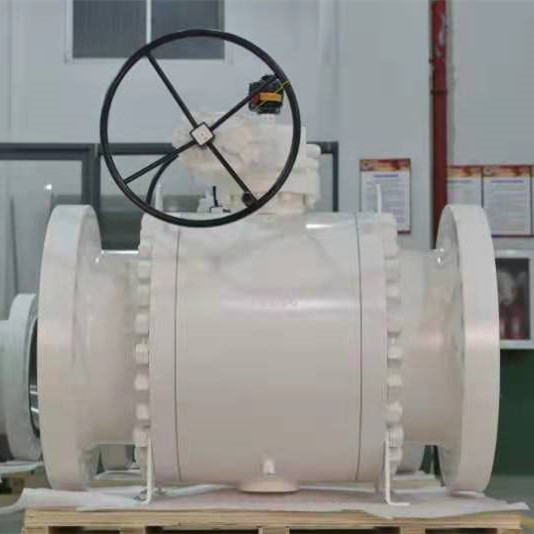

Trunnion ball valves are widely used in chemical manufacturing. They are ideal for transmitting large amounts of fluids over long distances. They are particularly suitable for use with strong bases and acids. These fluids can have extremely high temperatures, and using these valves can help prevent a dangerous situation.

Trunnion ball valves have a hollow center that allows fluid to flow in or out of the valve. They are used in applications where leakage is a major concern. Their design also allows them to be easily repaired. They are also highly reliable and have a small footprint.

Trunnion ball valves can be manufactured with forged steel. They are made by applying heat to solid steel blocks and using mechanical force to further process the steel. The result is a solid and hard-wearing valve that is able to withstand high temperatures. These valves can be used in many industries, including mining, agriculture, livestock handling, chemical processing, and aerospace.

Ten Things You Must Know About Metal-Seated Trunnioned Ball Valves

A trunnion ball valve consists of a stem and an inserting ball. Its trunnion design allows the ball to be inserted into a central bottom shaft. Trunnion ball valves are used for fluid control and are available in different varieties. Their main features include a low cost, reduced torque rate, and good corrosion and wear resistance. To learn more about this type of valve, read on. The following are some advantages and disadvantages of this valve.

- Emergency Seal

The emergency seal of a Trunnion ball valve can help to prevent an emergency shutdown. The seat of this type of valve can either be a hard or soft material. Soft materials offer better chemical compatibility and provide the tightest seal, but they’re prone to failure when exposed to abrasive or dirty liquids. Metal seated valves, on the other hand, can withstand higher temperatures and flash, which makes them a good choice for high-temperature applications.

- Antic Static

Antic-static features of a trunnion ball valve are critical to maintaining a safe process. They include features such as a trunnion blowout-proof stem and built-in anti-static devices. They also have extra wall thickness for increased corrosion resistance. They have been rigorously tested and certified according to API 6D and API 607 specifications.

- Blowout Proof Stem

The body of a trunnion-mounted ball valve is made from a number of materials. These include carbon steel, stainless steel, low-temperature carbon steel, Inconel, and duplex. The stem of a trunnion ball valve is the component that connects the actuator and the ball. The stem is a critical component of the valve and controls the movement of the ball. A blowout-proof stem of the trunnion ball valve can prevent a hazardous situation by eliminating this potential threat.

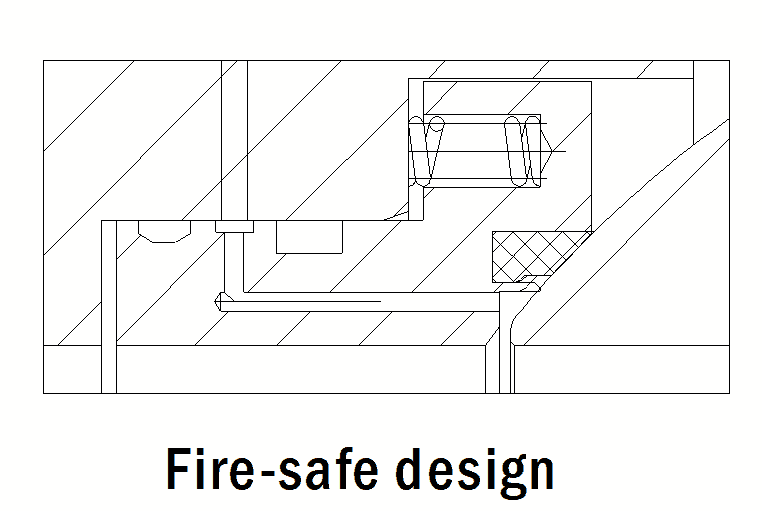

- Fire-safe design

The Trunnion Ball Valve has several key features that make it suitable for use in high-pressure systems. One of these features is its fire-safe design. This valve uses a graphite seal that can be separated into separate pieces. This seal is used to prevent leaks. Another feature of the valve is its flexible graphite packing.

- Has a compact build and lesser weight

The Trunnion Ball Valve has a compact build and lesser weight than other valve types. These valves are fire-safe and are less prone to environmental pollution. They are designed with high-quality materials that are resistant to chemical attack and abrasion. They are also tested to comply with API 607 and API 6FA standards.

- They are smaller size designs

There are many advantages of using a Trunnion Ball Valve for your application. These smaller-size designs are safe and fire-resistant. They are also able to withstand higher pressures and are a good choice for high-pressure applications. Trunnion Ball Valves are also often used in valve automation applications because of their ability to handle high flow rates.

- They minimize pressure drop resulting from reduced port valves

The trunnion ball valve is an ideal choice for reduced pressure drop applications. The design of a trunnion ball valve depends on the flow characteristics of the working fluid. The degree of opening of the valve determines the volumetric flow rate. The working fluid’s density and viscosity are also considered. The pressure drop (DP) is the difference between the pressure downstream of the ball valve and the upstream pressure.

- Have a wide industrial applications

Trunnion ball valves are often used in a wide range of industrial applications. They can be found in turbines, compressors, generators, separators, and polymer lines. They are also used in oil refinery feedstock lines and hydrocarbon processing.

- Lower torque rate

If you’re looking for a high-performance trunnion ball valve, there are several options to consider. This type of valve is highly durable, and its lower torque rate makes it an excellent choice for demanding applications. In addition, a trunnion-mounted ball valve is highly protected against damage from abrasive media. This allows it to operate in even the harshest conditions.

- Excellent corrosion and wear resistance

A Trunnion ball valve is a perfect solution for applications that require high corrosion and wear resistance. These valves come with a variety of features and connections, including electric and pneumatic actuation. They can handle various fluids, including hydraulic fluids, engine oil, and transmission fluid. They also feature excellent abrasion resistance. Stainless steel is also available for the best corrosion and wears resistance. Stainless steel also offers secure fitting and minimal leakage. These valves are preferred in applications involving chemicals or gases.

Located in the “valve city of China,” Yongqiang, Xintai Valve Co., LTD. is a professional stainless steel valve manufacturer. The company was founded in 1998 and is ISO9001-2000 and AZ-certified. It is dedicated to providing top-quality products and excellent service for its clients. Its products are used in various industries and have received API6D and AZ authentication.

XINTAI Valve has established itself as a world-class manufacturer of industrial valves. Its product line covers six categories and thousands of varieties, including ball, gate, cryogenic, and hydraulic control valves. Other types include thread and antibiotic valves. This makes Xintai a highly diversified company, allowing it to serve the needs of customers all over the world.